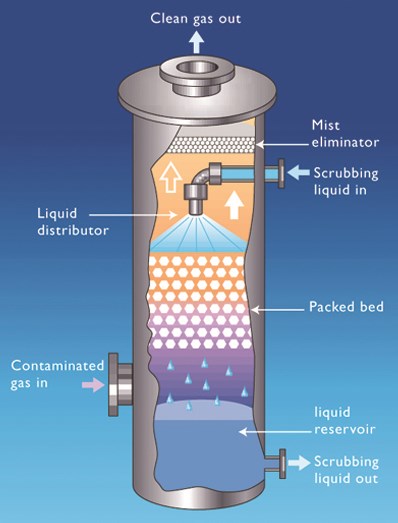

Water scrubbers are specially designed to remove impurities from raw gas. Let it be in

Distilleries, Breweries or fertilizer based, the BIG Group designed water scrubbers are

designed with complete SS internals and with the latest scrubbing technology so that

every molecule of CO2 is washed with water. CIP is the latest edition, where all the

scrubbers are equipped with auto CIP procedure.

The water scrubbers either it’s a High Pressure or Low Pressure both are designed to

maintain minimum water levels so that there is no loss of CO2 while washing.

BIG Group CO2 Compressors efficiently recovers CO2 from various sources providing food

grade CO2 that meets the highest quality standards in the industry. Designed to meet

each customer’s specific situation, the state-of-the-art CO2 recovery compressor offers

the lowest production costs per liquid CO2 tonne.

BENEFITS:

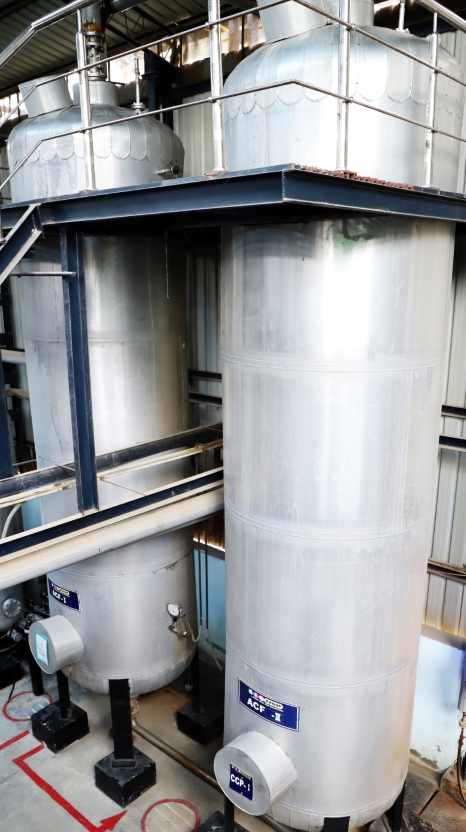

Activated carbon filter Beds are charged with small pieces of carbon pellets, typically

in granular form, that have been treated to be extremely porous. It is so cavernous, in

fact, that just one gram of activated carbon can easily have a surface area of 500m2 or

higher. Vast surface area enables these carbon filters to adsorb exponentially more

contaminants. The more porous the activated carbon is, the more contaminants it will

capture. These Beds are most notably used to remove hazardous compounds in CO2.

These beds are fully automated and in-case of distilleries and Breweries these ACF beds

are regenerated with steam.

BENEFITS:

Drier filter towers consist of molecular sieve. This material consists of pores (very

small holes) of uniform size. These pore diameters are similar in size to small

molecules, and thus large molecules cannot enter or be adsorbed, while smaller

molecules can. As a mixture of molecules migrate through the stationary bed of porous,

semi-solid substance referred to as a sieve (or matrix), the components of highest

molecular weight (which are unable to pass into the molecular pores) leave the bed

first, followed by successively smaller molecules.

BIG Group drier filters are designed to remove complete moisture from the running

stream with results up-to 0.1 PPM. The ISBT approved standard for moisture is 20 PPM,

but we design our dryers to get consistent stream of 0.1 PPM, which is a great

milestone achievement in the industry.

Applications:

BIG Group screw compressor packages are

used in a wide range of industrial refrigeration applications.

All of our compressor packages are built to ensure maximum reliability and efficiency,

operational safety, trouble-free operation, and easy maintenance.

Screw compressors are also positive displacement cooling system components.

As one screw and twin-screw compressors are widely used in refrigeration.

One of the screw compressor consists of one screw rotor (shaft)and a pair of gates

rotors, which are then grid and together with the form of the case of pressurized

volume, which

is compressed.

Highlights & Technical features:

In addition, BIG Group screw compressors can be provided with other refrigeration system components such as evaporators, condensers, and pressure vessels in a factory-assembled, pre-piped and pre-wired package.

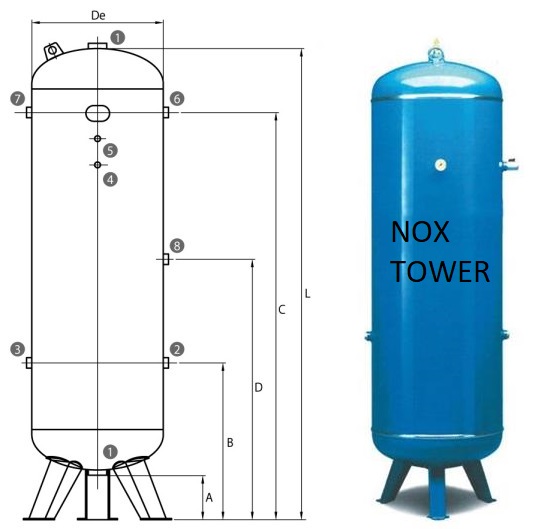

NOX tower consists of special designed grade of molecular sieves. The same adsorbs

molecular with a kinetic diameter of less than 9 Angstroms and exclude the larger ones,

which is exclusively suitable for the removal of NoX compounds in Liquid Carbon

Dioxide.

Applications: